Innovative Techniques to Fillet Weld Examination and Screening: Enhancing Weld High Quality and Compliance Standards

In the realm of welding, the quality and honesty of fillet welds play a crucial function in making sure the structural strength and reliability of different commercial parts. With the constant drive for improved effectiveness and compliance with rigid requirements, the expedition of innovative approaches to fillet weld examination and testing has become vital. As sectors progress, the standard methods may no longer be sufficient in fulfilling the needs of modern-day welding applications (Gauge Fillet Weld). By accepting advanced innovations and methodologies, a brand-new horizon of opportunities arises in the realm of weld top quality analysis and adherence to conformity criteria.

Advanced Non-Destructive Testing Techniques

Utilizing modern modern technologies, advanced non-destructive testing methods play a crucial duty in ensuring the integrity and high quality of fillet welds. These methods, such as phased range ultrasonic screening (PAUT) and magnetic particle screening (MPT), deal comprehensive insights right into the weld's interior structure without creating any type of damage to the product. PAUT, for example, utilizes multiple ultrasonic components to evaluate the weld from various angles, providing a detailed visualization of possible flaws like lack of fusion or fractures.

By using these advanced non-destructive testing strategies, weld examiners can properly evaluate the top quality of fillet welds, guaranteeing conformity with market criteria and policies. The capacity to find imperfections early on not only enhances weld top quality but additionally avoids expensive rework or failures in structural honesty, highlighting the relevance of these cutting-edge screening methods in welding examinations.

Robotics and Automation in Examination

The combination of robotics and automation has changed the inspection process for fillet welds, improving performance and accuracy in high quality evaluation. Robotics supply specific control and repeatability in examining welds, making certain consistent and reliable results. Automated systems can be programmed to comply with specific inspection courses, ensuring extensive coverage of welds and decreasing the danger of human mistake.

Robotic assessment systems outfitted with innovative sensing units can discover and determine weld attributes with high precision, offering thorough information for analysis. These systems can determine issues such as splits, lack of blend, and porosity, allowing timely restorative actions to be taken. Additionally, robotics and automation enable real-time information collection and analysis, providing prompt responses to operators and facilitating fast decision-making procedures.

Furthermore, using robotics and automation in fillet weld evaluation improves overall efficiency by minimizing evaluation times and boosting assessment throughput. By simplifying the evaluation procedure, producers can guarantee weld quality and conformity requirements are met successfully, ultimately bring about set you back financial savings and improved item quality.

Making Use Of Artificial Knowledge for Analysis

Expert system plays a crucial role in enhancing the performance and accuracy of analysis in fillet weld assessment processes. By using the power of AI, inspectors can improve the evaluation of weld high quality and conformity criteria, leading to more reputable and precise outcomes. AI formulas can swiftly process large amounts of data from weld evaluations, discovering defects or incongruities that might be challenging to recognize with the nude eye. This advanced modern technology makes it possible for real-time tracking of weld quality, permitting prompt restorative activities to be taken if any type of issues are discovered.

Moreover, AI systems can find out from past assessment data, continuously improving their capacity to identify possible problems and deviations in fillet welds. This flexible learning capacity enhances the general high quality control process, minimizing the likelihood of human mistake and making certain that welds fulfill the needed requirements. By incorporating fabricated intelligence right into fillet weld analysis, markets can attain greater levels of effectiveness, consistency, and conformity in their examination practices.

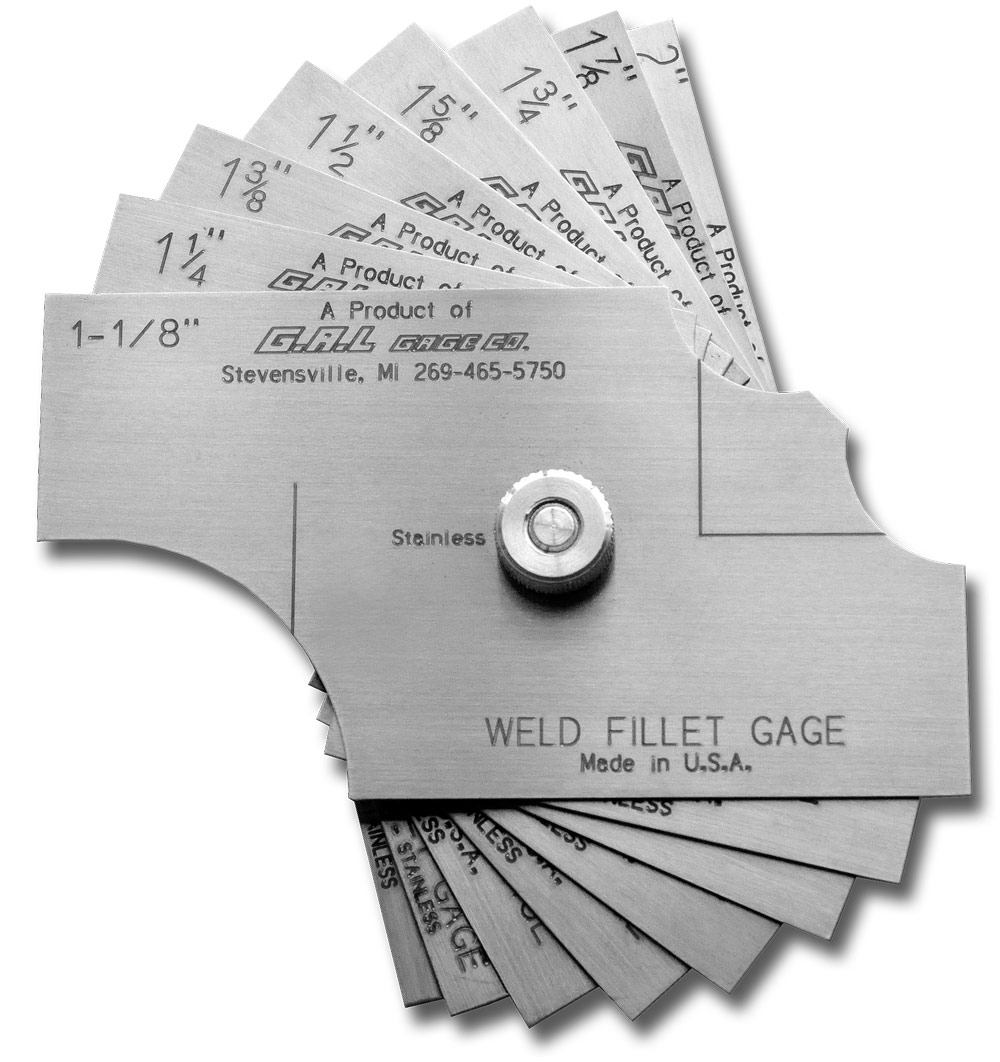

Portable Tools for On-Site Assessment

Enhancing area evaluation efficiency, the fostering of portable devices changes on-site analysis processes for fillet welds. These devices supply adaptability and convenience, enabling assessors to carry out complete read here exams in numerous areas, including tough or remote atmospheres. Portable tools such as ultrasonic testing tools, magnetic particle inspection devices, and electronic radiography systems offer real-time information and high-resolution imaging abilities, enabling fast decision-making and prompt feedback on weld quality.

One considerable benefit of mobile tools is their ability to simplify evaluation treatments, reducing downtime and improving general productivity - Gauge Fillet Weld. Inspectors can conveniently transfer these devices to various task websites, eliminating the requirement for delivering heavy equipment or components to off-site centers. Additionally, the transportability of these devices promotes cost-effectiveness by lessening transport costs and accelerating examination timelines

Additionally, making use of mobile devices for on-site inspection advertises positive quality assurance procedures, as inspectors can quickly identify and resolve any type of prospective welding problems or inconsistencies. By integrating these innovative modern technologies into on-site evaluation practices, welding specialists can ensure conformity with industry criteria and improve weld top quality, eventually leading to improved structural honesty and security in numerous welding applications.

Integration of Information Management Systems

Having actually enhanced on-site examination procedures with the usage of portable devices, the following stage entails the seamless combination of information monitoring systems to additionally improve performance and data evaluation capabilities in fillet weld examination and screening. By integrating information monitoring systems into the examination procedure, companies can simplify data collection, storage space, and evaluation. This combination enables real-time tracking of weld high quality, immediate recognition of defects, and prompt decision-making to remedy any issues that might arise during the examination procedure.

Information monitoring systems play an important role in centralizing inspection information, promoting very easy access for authorized employees, and ensuring information honesty and security. Through the assimilation of these systems, examiners can produce comprehensive records, track from this source historical data for pattern analysis, and boost overall process effectiveness. Moreover, the combination of data monitoring systems makes it possible for seamless interaction in between various stakeholders entailed in the evaluation process, fostering collaboration and improving general top quality control actions. Inevitably, the assimilation of data management systems offers to elevate the requirements of fillet weld inspection and testing, making sure compliance with industry laws and improving weld high quality.

Conclusion

In conclusion, cutting-edge techniques to fillet weld inspection and testing have dramatically improved weld high quality and compliance criteria. Advanced non-destructive screening methods, robotics, automation, expert system, mobile tools, and information administration systems have actually reinvented the way weld evaluations are performed. By using these modern technologies, industries can guarantee that welds satisfy the required quality standards and policies, inevitably enhancing general performance and security in welding processes.

Having actually enhanced on-site assessment processes with the usage of mobile devices, the following stage includes the smooth integration of information monitoring systems to even more enhance performance and data evaluation capacities in fillet weld examination and screening. Eventually, the assimilation of data monitoring systems offers to elevate the criteria of fillet weld evaluation and screening, making certain conformity with sector policies and improving weld top quality.

Comments on “Recognizing Gauge Fillet Weld: A Comprehensive Guide for Welders”